■ ACMT/ 邱耀弘

序言

Introduction of authors:Dr. Qiu is the leader of MIM industry in Greater China area. Establishment of “You need” technology office with Mr. James in 2019. We are determined to promote MIM Technology forever .Our advisor y ser vices have spread throughout Greater China and Japan. Let us work together for the revitalization of MIM industry in Asia.作者介紹:邱耀弘博士是大中華地區的MIM 產業領頭人物,與趙育德先生在2019 年創立耀德講堂,矢志為MIM 技術而潛力推廣,我們的顧問服務已經遍及整個大中華地區與日本,為亞洲地區的MIM 產業振興而努力。

News 新消息

S h e n z h e n I n t e r n a t i o n a l M I M a n d A d d i t i v e Manufacturing Technology summit to be held in Shenzhen, China from September 26 to 28, 2019. This is the extension of PM China’s annual first quarter meeting. Every year’s meetings of the East (Shanghai)

and South (Shenzhen) bring together the power of the powder industry. Among them, it represents the two focal points of China’s MIM market – the Yangtze River Delta Economic Zone in East China and the Pearl River Delta Economic Zone in South China (Guangdong-Hong Kong-Macao Greater Bay Area in the future). Especially in South China, where smartphones are made in China. This is why MIM products factories in Shenzhen and Dongguan are the most dense areas of the world. It is also the area where several mobile phone manufacturers (OPPO, Vivo, and Huawei, top three of China) and overseas customers (A & G) are the most intensive. Here, there are the latest MIM smartphone parts design and mass production settlements of global. 2019 年9 月26~28 日在深圳舉辦的深圳國際注射成型及增材製造技術與應用峰會,這是PM China(中國粉末冶金業界)擴展每年第一季會議的延伸,每年一東一南的會議凝聚了粉末行業的力量,其中更代表了中國MIM 市場的兩個聚焦點位置 – 華東地區的長三角經濟區和華南地區的珠三角經濟區(未來是粵港澳大灣區),尤其是華南地區是中國智慧手機的製造重鎮,光是在深圳和東莞兩地的MIM 製品工廠,就是全球密度最高的地域,也正是中國幾家手機製造廠(OPPO、Vivo、華為前三大)、海外客戶(A & G)公司代工廠最密集的區域。這裡有全球最新的MIM智慧手機零件設計並大量生產的聚落。

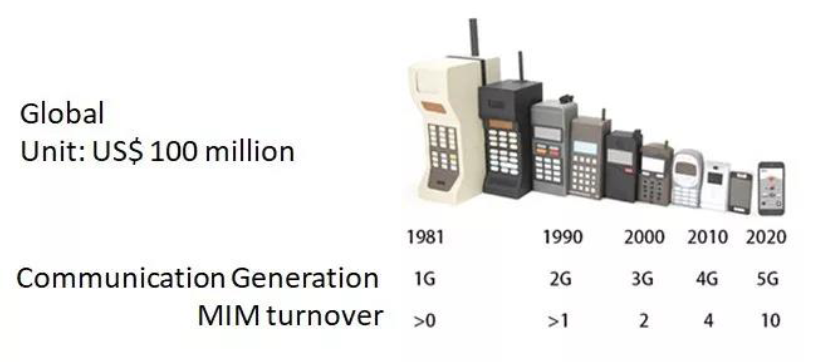

Of course, everything in here is to meet the next 5G communication efforts.To face the high-speed transmission of 5G era, where is the opportunity for MIM? Listen to Dr. Q and James for your analysis. See Figure 1. Looking at each generation of mobile networks and telecommunications technology upgrades, it happens that there is a corresponding proportional growth relationship with MIM’s global gross product. We can say that the upgrade of mobile communication technology alternates with the generation. Due to hardware requirements, MIM technology can meet its requirements. Therefore, MIM industry can rely on the upgrading of mobile communication technology and flourish.

理所當然,在這裡的一切無不為了迎接最新的5G 通訊到來而努力,在高速傳送速率的5G 時代來襲,MIM 的機會在何方呢?且聽Dr. Q 和James 為大家解析一番。請見圖1,觀察行動電話網、通信技術的每個世代升級,恰巧與MIM 全球總產值有相對應的正比成長關係。我們可以說,移動通信技術的升級與世代交替,由於硬體上的需求,正好MIM 技術能夠符合其要求,因此MIM 產業得以依賴移動通信技術升級而蓬勃發展。

Destructive Innovation 破壞式的創新

Since its advent in the 1970s, MIM technology has destroyed other traditional technologies, such as investment casting, die casting, stamping and machining, in processing of small metal parts. It also suppresses the new rising stars such as liquid metal, 3D metal printing, and so on. Because metal parts are manufactured as quickly and in large quantities as plastics by using the design and processing patterns of plastic injection molding, which has the characteristics of molding and material selection of powder metallurgy. More than 12% shrinkage ratio makes products details clearer of each feature. Small size and light weight coincide with the need to carry and wear electronic devices. The key point is that prices can also keep pace with the smartphone industry and continue to survive. MIM technology has several advantages of destructive innovation.

MIM 技術自1970 年代問世以來,就是以「破壞式」姿態在小型金屬零件的加工席捲其他傳統技術,例如精密鑄造、壓力鑄造與衝壓機加工製品,也打壓著後起之秀如液態金屬、3D 金屬列印等。因為利用塑膠射出成型的設計與加工型態,把金屬零件像塑膠一樣的快速、大量製造出來,並具有造型和粉末冶金材質選型的特色,超過12% 收縮比使得產品細節更清晰,與小尺寸且輕薄短小的攜帶、穿戴式電子裝置的需求不謀而合,重點是價格還能夠屢創新低的跟隨智慧手機產業延續生命,這便是MIM 技術具有破壞式的創新的幾個優點。_

圖1:移動電話網、通信技術世代的升级恰巧與全球MIM 總產值有相對應的正比成長關係

Requirements from the 5G era 5G 時代的需求

❶ Miniature lifting mechanism 微型升降機構

Everyone knows that in order to improve the overall screen ratio of smartphones and avoid copying screen design of “foreigners’”(the placement include:sensors, front camera modules, and receiver). A mechanism using the micro gear reduction module as a hidden camera begins in the second half year of 2018, as shown in Figure

- The micro gear reduction module has become a highlight of smartphones in 2019 on China.

Estimated demand exceeds 2 billion sets of 2019,include: micro gears (less than 1mm in diameter),micro cylindrical gears, and internal gear modules.Total MIM parts have at least 12 parts.大家很清楚為了提升智慧手機全面屏占比,避免抄襲外國人的屏頭感測器與前置相機模組的瀏海設計,利用微型齒輪減速模組作為隱藏式相機的機構在2018下半年開始,如圖2. 微型齒輪減速模組,成為2019年中國智慧手機的一大亮點,需求超過2 億組,包含微型齒輪(直徑小於1mm)、微型柱狀齒輪與內齒輪模組,MIM 的零件至少有12 件。

➋ Strengthen mechanism of camera lens module 相機鏡頭模組強化機構

It seems that MIM technology came to overthrow traditional cameras. A smartphones are based on high-speed communications technology in the 5G era, in addition to sharing wonderful and interesting photos. Camera on smartphones also have many functions like beauty face, Eliminating miscellaneous image, and personal confidentiality authentication. They use multi-lens and sensors to perform all the above functions because of the shortcomings of traditional cameras which have only one lens. Therefore, the lens and sensor are plural outlets, and the correct position of these precise modules between each other is particularly important, as shown in Figure 3. How to make use of high strength and unequal thickness of metal to reinforce locally? In the design of smartphone camera project, a solid, non-residual magnetic, conductive and fast heat dissipation metal material is needed as a design of a combination of several complex functions. Don’t forget, many people puttheir mobile phones in their back pockets. The stress extrusion during the use process should always ensure that the camera function is correct. Only the lens protection ring made by MIM technology is the first choice of mainstream design.

圖2:微型齒輪減速模塊,搭配微小的電機驅動機構升縮,可作為攜帶裝置上的升降機構,例如隱藏式相機或鏡頭升縮等需求

似乎MIM 技術就是為了推翻傳統照相機而來,智慧手機在5G 時代的高速通信技術基礎上,除了分享精彩有趣的照片外,相機還要擔負美顏、過濾雜像、個人保密認證的功能,把原來傳統相機只有單鏡頭的缺點,利用多鏡頭加上感測器來進行上述功能,因此鏡頭與感測器需要複數的出口,這些精密的模組彼此之間的位置正確性格外重要,如圖3. 所示,如何利用金屬高強度、不等肉厚局部補強,智慧手機相機工程在設計上需要一片堅固、不殘磁、能導通、快速散熱的金屬材料,作為幾個複雜功能一次組合的設計,別忘了,很多人手機放在後口袋,使用過程的擠壓,始終要保證相機功能無誤,MIM 技術製作的鏡頭保護圈已經成為主流設計。

➌ Integration of intensification and water proof design of various I/O connector各種I/O 介面的強化與防水設計整合

The coming of 5G era, a high-speed transmission smart phone must be in clued an original power switch, volume buttons, signal transmission ports, outlet of the multi-point antennas, and position of the camera module, them need waterproof and dustproof design. With the compatible design of MIM parts combine plastic and silica rubber, users can use their mobile phones safely in desert, rainy day, bathing and hot spring, very easy to share their life pictures with their families and friends. Don’t forget that other wearable electronic equipment, such as watches, earphones, sport bracelets, MIM parts plus waterproof and dust-proof design, is absolutely necessary to “destroy”.5G 時代的來臨,一部高速傳輸的智慧手機除了原來的電源開關、音量按鍵、信號傳輸口,還有多點天線的出口和相機模組升縮位置,都必須進行防水防塵的設計,利用MIM 零件設計與塑膠、軟矽膠的相容設計,使用者可以在沙漠、雨天、洗澡與泡溫泉,都能安心無虞的使用自己手機,分享生活點滴給家人和朋友。別忘了,其他穿戴式電子裝備如手錶、耳機、運動手環,MIM 零件加上防水防塵的設計,絕對是必要的「破壞」。

➍ Not only mobile device, 5G system needs more support其他5G 時代的裝置需求,不只手機

There is a saying that “only one coin will not ring.” in China. Yes, terminal equipments of 5G signals have vast industry of smartphones, tablet computers and wearing devices, and a number of signal boxes as the carrier of intermediate transmission, conversion, and indoor/outdoor, mobile tools, above all, all kinds of a huge numbers. With environmental requirements, not traditional plastic materials and sheet metal materials can be competent, we must use MIM metal parts. MIM parts can integrate multiple functions in one design, to simplify the weight loss, light and thin, as well as external decoration design在中國有句俗語「僅有一個銅板不會響的」,是的,5G 信號的終端設備是有廣大的智慧手機、平板電腦、穿戴裝置產業,而作為中間傳輸轉換的載體 – 信號機盒的數量也不在少數,而且室內與戶外、移動工具的上面,各種不同環境要求,不是傳統塑膠材料與板金材料可以勝任的,必須利用MIM金屬零件這個可以整合多種功能於一體的設計,來達成減重與輕薄化,並兼具外觀裝飾的設計。

201

201

圖3. 以MIM 技術製造的鏡頭保護圈,必須確保鏡頭模組和感測器的相對正位,還要包含多種功能性要求:外觀亮眼、不殘磁、能導通、能導熱,甚至是生物相容要求。

Material-led MIM Technology材料領軍的MIM 技術

With the advent of high-speed communication technology in the 5G era, MIM is also facing an important era of hidden needs. Physically, it is difficult to solve the problem with both traditional technology and EMC, heat dissipation, current conduction and mechanism positioning. These problems must be assisted by material science and technology. Therefore, there is a sharp increase in the demand for metal parts with different materials using MIM technology in 5G communication signal receiving boxes, local servers and terminal devices. For example, besides the traditional stainless steel as structural parts, the heat dissipation and electromagnetic isolation function of copper based alloys and the non-magnetic height of cobalt-based alloys are also required. Strength, magnetic conductivity of nickel-based alloys, high specific gravity tungsten alloy oscillator, and even inexpensive reinforcement function of iron-based

alloys structure, etc., constantly bring forth new and destructive innovations to replace the previous design.在5G 時代高速通信技術來臨後,MIM 也面臨到更加廣泛的隱藏性需求。在物理上難以透過傳統工藝解決的電磁相容、散熱、電流導通以及機構定位等問題,就必須依賴材料科技來協助,因此在5G 通信的信號接收盒與局端伺服器、終端裝置上,採用MIM 技術包含不同材料的金屬零件需求遽增,除傳統的不銹鋼作為結構件外,還有銅基合金的散熱與電磁隔離功能、鈷基合金無磁高強度、鎳基合金的導磁特性、高比重的鎢合金振子、甚至便宜的鐵基合金結構補強功能等,不斷的推陳出新以破壞式的創新來取代以往的設計。

Before the advent of 5G era, MIM material advancement in the post-4G era includes: 細數5G 時代來臨前,後4G 時代MIM 材料推進包含:

- P.A.N.A.C.E.A: a high nitrogen nickel-Free stainless steel – it is a non-residual magnetism and high strength Iron-Based Alloy. 高氮︑無鎳的不銹鋼 – 不殘磁、高強度的鐵基合金。

- D2507 and 904L: stainless steels with high hardness and high brightness-first choice for watch appearance decoration 高硬度、高亮度不銹鋼 – 手錶外觀裝飾首選。

- HK30: heat resistant high strength steel. 耐熱、高強度的鋼 。

- ASTM F75 Co-Cr-Mo Alloy:non-residual magnetic material with high toughness and strength 鈷鉻鉬合金– 高韌性、高強度的不殘磁材料。

- A286:Nickel-based superalloy-high hardness without residual magnetism. 鎳基超合金 – 不殘磁且高硬度。

- Inconel 718 & 713: Nickel base superalloy-nonresidual magnetic material with high toughness and strength and high temperature resistance. 鎳基超合金 – 高韌性、高強度的不殘磁材料,且耐高溫。

- W-Ni-Fe & W-Ni-Cu W-Ni-Fe and W-Ni-Cu high specific gravity alloys-counterweight and vibration warning. 鎢鎳鐵與鎢鎳銅高比重合金 –配重與震動提醒。

- Cu and copper alloys – heat dissipation and magneto resistance. 銅合金 – 散熱且磁阻。

Conclusion 結論

MIM will be the best partner for mechanism design in 5G communication with multi-morphology parts and composites. Don’t leave the distance behind. MIM technology is always at your side. There are more than 200 MIM products factories in China that can help you enter the 5G era.以多形貌零件、複合物理量解決之道,MIM 將是5G通信中機構設計最佳的夥伴,別捨近求遠,MIM 的技術隨時在您的身邊,在中國有超過200 家的MIM 製品廠能協助您進入5G 時代呢~ ■